Call us : 0207 117 2087

Email : info@halohvac.co.uk

Integrating IoT

with AHU Refurbishment

for Sustainable HVAC Upgrades

In a world increasingly focused on sustainability, the urgent need to integrate new technology into existing buildings becomes essential to meet ambitious net-zero objectives.

While there are certainly cost-effective measures available, such as the installation of LED lighting and thermal insulation, which yield favorable returns on investment, they merely represent the tip of the iceberg in the pursuit of sustainable objectives. These technologies, while beneficial, only scratch the surface of what is necessary to truly transform buildings into beacons of environmental responsibility.

Air Handling Units (AHUs) play a vital role in maintaining indoor air quality and thermal comfort in buildings. However, they are significant energy consumers. HVAC systems account for around 40% of a building's total energy usage. With sustainability becoming a global priority, refurbishing AHUs presents an opportunity to reduce energy consumption and carbon footprint.

What is an AHU Refurbishment Project?

AHU refurbishment is a cost-effective solution that ensures compliance with regulations, extends the unit's life by 10-20 years, and improves energy efficiency. It's a strategic investment for modernizing your HVAC system and aligning with sustainability goals.

An air handling unit refurbishment project involves the overhaul and modernization of existing HVAC systems to enhance efficiency, performance, and indoor air quality. This comprehensive endeavor typically encompasses various upgrades, such as the installation of energy-efficient EC (electronically commutated) fans to improve airflow, reliability, and reduce energy consumption. Additionally, coil replacements are often undertaken to ensure optimal thermal transfer and temperature regulation within the system.

Throughout the refurbishment process, rigorous validations are conducted to verify that the unit meets industry standards, design specification and regulatory requirements.

A key focus lies on improving Indoor Air Quality (IAQ) by incorporating advanced filtration systems and ventilation strategies, ultimately creating a healthier and more comfortable environment for occupants.

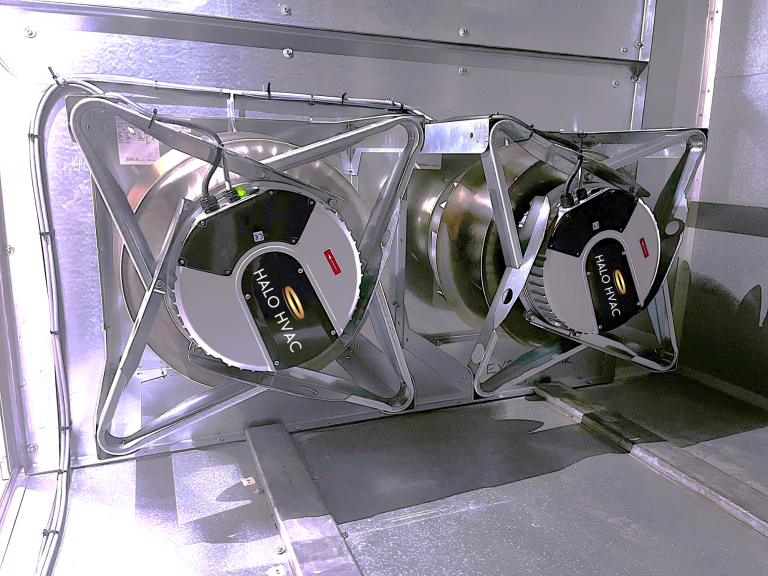

EC Fan Upgrades

HALO HVAC precisely selects the optimal EC plug fan for each application, relying on thorough validations to achieve peak efficiency without sacrificing performance. This process includes detailed considerations of air volume, pressure, and specific application requirements.

Our sophisticated solutions include N+1 redundancy, guaranteeing uninterrupted operation even in the event of a fan failure.

By harnessing the power of EC plug fans in an accurately designed fan array, critical environments attain unparalleled levels of airflow control, thermal management, and operational resilience.

Where does IoT come in ?

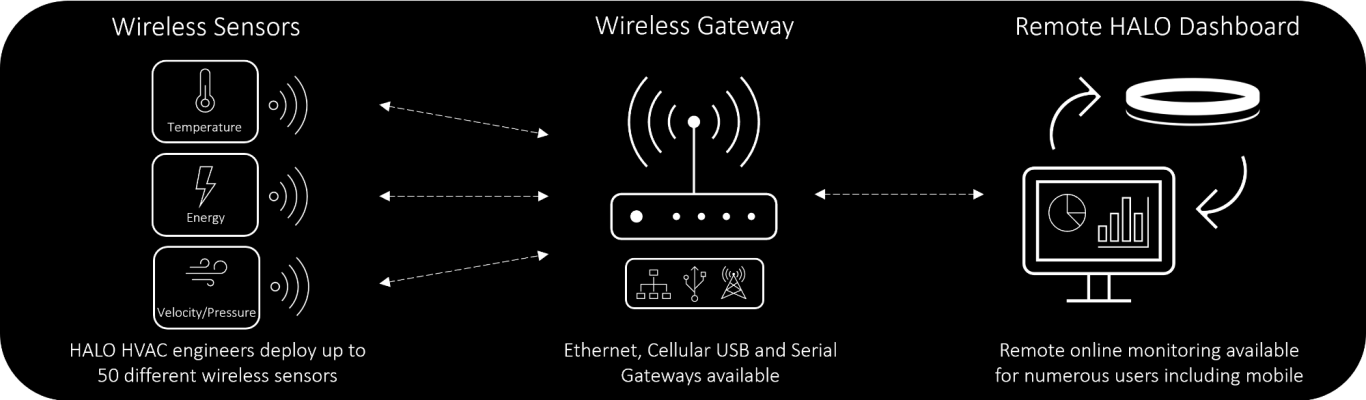

HALO HVAC IoT sensors enables real-time monitoring for quick issue resolution, energy efficiency optimization, predictive maintenance, and remote control.

Wireless IoT sensor technology provides real-time remote monitoring and data analytics capabilities essential for optimizing AHU and HVAC system performance.

Our IoT sensors can collect data on various parameters such as temperature, humidity, CO₂, air pressure, air velocity, IAQ, particulate matter, energy consumption and more.

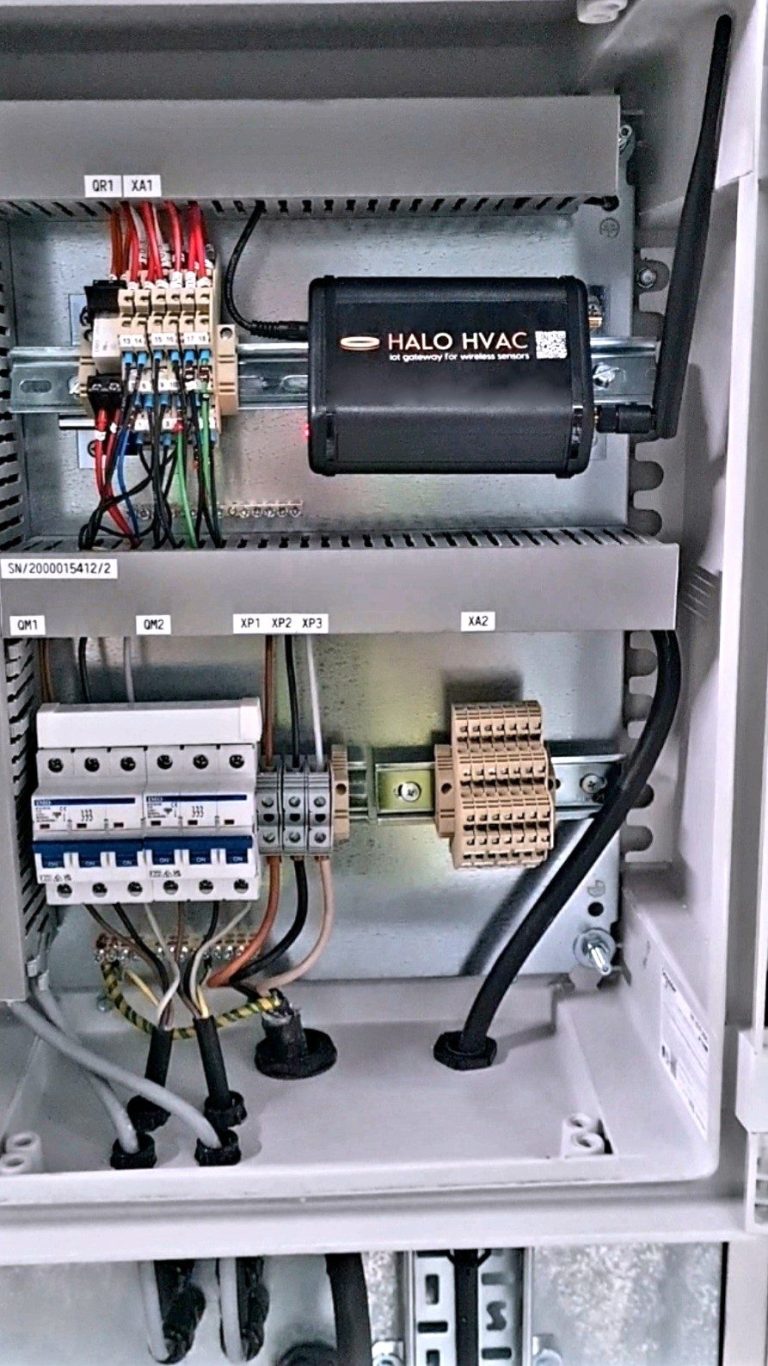

Paired with the IoT gateway, data is securely sent to the HALO to allow our team of experts to analyze the data and performance. The integration of IoT sensor technology within an AHU refurbishment project enables a holistic approach to energy and facility management.

Integration

Integrating HALO HVAC IoT sensors as part of the AHU refurbishment process allows our team and clients to accurately understand, analyze, validate, and maintain system performance remotely. Understanding the air handling unit performance is vital to ensuring an AHU refurbishment project is completed successfully.

By utilizing our range of wireless IoT sensors, we can obtain valuable insights into existing operational performance. This allows us to interpret whether current system performance is meeting the required air change rates, pressures, temperatures, and indoor air quality parameters.

Real data

After analyzing the data obtained from the IoT sensors, we can formulate a comprehensive project plan to carry out the necessary upgrades to an air handling unit to achieve agreed objectives such as improved air quality or enhanced energy efficiency.

IoT can facilitate predictive maintenance by collecting and analyzing data from HVAC equipment. Sensors can detect early signs of potential issues or equipment failures, allowing for proactive maintenance to prevent breakdowns and reduce downtime.

Following the completion of an Air Handling Unit refurbishment project, the HALO HVAC wireless IoT sensors can be utilized to verify and validate the upgraded system performance.

This process entails analyzing the original data alongside the updated data to evaluate the range of improvements implemented in the system, including measures for energy savings and any proposed return on investments (ROIs).

The HALO HVAC team collaborates closely with energy and facility managers to find ways to optimize energy usage and perform predictive maintenance, all while ensuring system performance and occupant comfort are not compromised.

Retrofitting a sustainable future

We are shaping intelligent infrastructure that not only meets the needs of today but actively contributes to a healthier planet for future generations.

HALO HVAC's commitment to innovation serves as the cornerstone for a transformative shift in energy management and operational efficiency within the realm of HVAC systems.

Through a forward-thinking approach, HALO HVAC has positioned itself as a pioneer in harnessing cutting-edge technologies to drive environmental sustainability and economic prosperity.

At the heart of this transformative vision lies the integration of HVAC energy upgrades.

By seamlessly retrofitting advanced technologies and components, HALO HVAC enables air handling units to operate at peak efficiency levels.

The strategic fusion of technologies such as EC plug fans with IoT sensors enables real-time monitoring and data analytics, propelling efficiency gains to unparalleled heights.

Welcome to the future of effortless, efficient HVAC.

Revolutionize your HVAC system with our state-of-the-art HVAC IoT sensors. Our expert team not only supplies but also installs our advanced weatherproof sensors, ensuring precision in HVAC monitoring air quality, temperature, velocity, humidity, energy and more.

Ultimate Security Measures—Benefit from HALO's exclusive encryption protocols, ensuring the protection of your data during transmission with bank-grade security. click here for more info

Multiple Secure Signal Network Options - Achieve signal transmission spanning over 2,000 feet and penetrating through 18 or more walls utilizing HALO IoT sensors and Ethernet Gateways

Exceptional Battery Longevity—Enjoy over a decade of hassle-free performance with just 2 AA batteries

50+ Dedicated HVAC Sensors For Every Application

The industry’s broadest line of HVAC wireless IoT sensors will cover your remote HVAC monitoring needs from power & air quality to velocity, humidity, temperature, air pressures and much much more

HALO HVAC IoT sensors & software can work independently on mobile & PC,

or seamlessly integrate to your existing BMS and controls strategy. Compatible with;

Conformity & Compliance

HALO HVAC Ltd has passed industry leading conformity and compliance testing, verification, and inspection. Our accreditations highlight our technical competences, reliability, and integrity to provide confidence and trust to deliver our services.

We hold insurances for Contractors All Risk, Professional Indemnity, Employer Liability, Public and Product Liability, and Contract Works. We are members of Constructionline, Building Engineering Services Association (BESA), and The Contractors Health and Safety Schemes in Procurement (CHAS Advanced) including PAS91 and SSIP.

Call to request copies on 0207 117 2087 or email info@halohvac.co.uk

Latest News

HVR Awards

We are honoured to create a partnership with Heating Ventilation Review for the 2024 HVR Awards!

NEW - White Paper :

Learn how Integrating IoT with AHU refurbishment enables sustainable HVAC energy upgrades.

Case Study : Cutting carbon by removing on-site gas-fired boilers and remodelling the AHU's by adopting new DX heat pump technology.

Case Study : 13 AHU's serving a critical manufacturing process and science labs, upgraded and delivered in less than 5 days.

Case Study : Ministry of Defence (MOD) Decarbonisation through

AHU Refurbishment & New Cutting-Edge Air Source Heat Pumps.

Nominated for Two Awards :

Thrilled to announce we have been shortlisted for both, Building A Safer Future Award & Building Services Project of The Year !!

Case Study: This luxury 5* Mayfair hotel operates 24/7 - Therefore, we delivered this project with zero disruption to guests and services.

NEW: CPD and Training sessions by HALO HVAC experts - certified content for HVAC industry professionals.

We need your consent to load the translations

We use a third-party service to translate the website content that may collect data about your activity. Please review the details in the privacy policy and accept the service to view the translations.